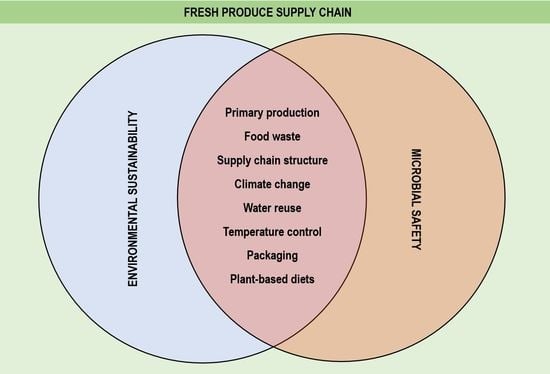

Improving the environmental sustainability of the food supply chain will help to achieve the United Nations Sustainable Development Goals (SDGs). This environmental sustainability is related to different SDGs, but mainly to SDG 2 (Zero Hunger), SDG 12 (Responsible Production and Consumption), SDG 13 (Climate Action), and SDG 15 (Life on Land). The strategies and measures used to improve this aspect of the food supply chain must remain in balance with other sustainability aspects (economic and social). In this framework, the interactions and possible conflicts between food supply chain safety and sustainability need to be assessed. Although priority must be given to safety aspects, food safety policies should be calibrated in order to avoid unnecessary deleterious effects on the environment. In the present review, a number of potential tensions and/or disagreements between the microbial safety and environmental sustainability of the fresh produce supply chain are identified and discussed. The addressed issues are spread throughout the food supply chain, from primary production to the end-of-life of the products, and also include the handling and processing industry, retailers, and consumers. Interactions of fresh produce microbial safety with topics such as food waste, supply chain structure, climate change, and use of resources have been covered. Finally, approaches and strategies that will prove useful to solve or mitigate the potential contradictions between fresh produce safety and sustainability are described and discussed. Upon analyzing the interplay between microbial safety and the environmental sustainability of the fresh produce supply chain, it becomes clear that decisions that are taken to ensure fresh produce safety must consider the possible effects on environmental, economic, and social sustainability aspects. To manage these interactions, a global approach considering the interconnections between human activities, animals, and the environment will be required. View Full-Text